Why Hot Foil Stamping is So Eye-Catching?

In today’s crowded market, standing out is more important than ever. Every brand wants its products to catch the eye. But with so many choices on the shelves, it is not easy for any product to get noticed.

Packaging boxes are often the first thing customers see. They are the first physical interaction a customer has with your brand. A well-designed packaging box can make a big difference. It can encourage a customer to pick up your product instead of walking past it. One of the best ways to make your packaging stand out is by using special finishing techniques. Hot foil stamping is one such technique. It immediately communicates quality, luxury, and attention to detail.

What is Hot Foil Stamping?

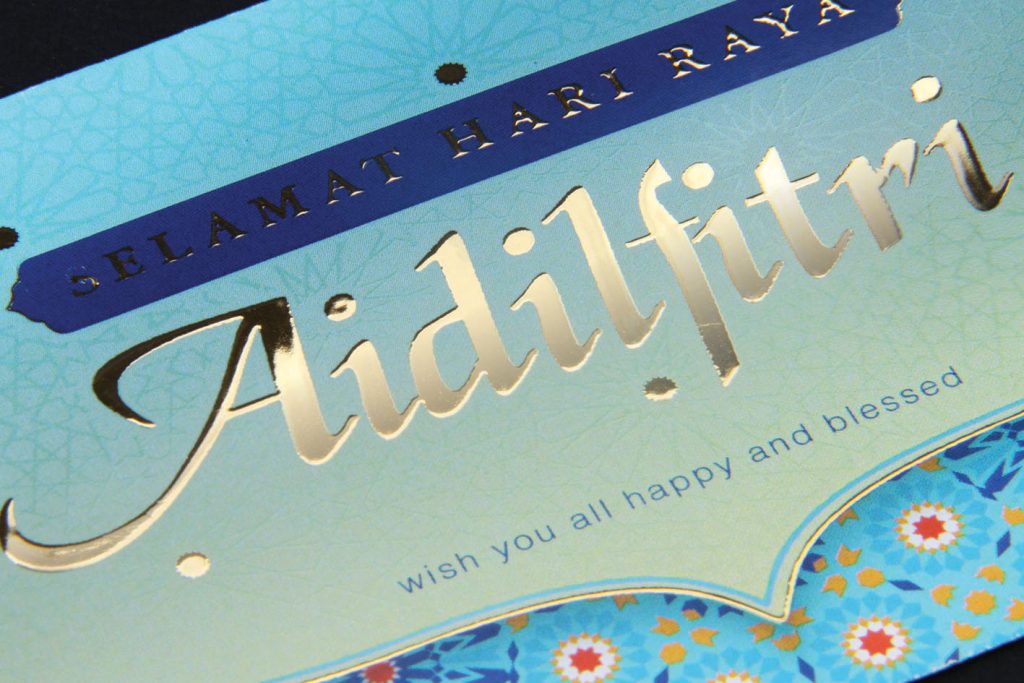

Hot foil stamping is a process that uses heat and pressure to transfer metallic or colored foils onto surfaces. These surfaces include paper, carton board, laminated board, plastics, and corrugated board. The result is a shiny, reflective finish that is both visually appealing and tactile.

In Malaysia, hot foil stamping is often associated with premium and luxury products. Gold and silver foils are the most popular choices. They convey elegance, exclusivity, and value. Colored foils are also becoming more popular. They help brands match the foiling to their logo or brand colors.

When used in custom packaging box printing in Malaysia, hot foil stamping sends a strong message. It tells customers that your product is high-quality. It shows that you care about every detail of your brand.

Why Hot Foil Stamping Works

Foil stamping is not just visually attractive. It also works on a psychological level. Shiny metallic finishes naturally attract attention. People are drawn to reflective surfaces.

Research from the Foil & Specialty Effects Association (FSEA) shows that packaging with foil catches a customer’s eye faster and holds attention longer than standard packaging. In one study on disposable coffee packaging, boxes with gold foil were noticed 2.5 times faster than plain packaging.

Hot foil stamping also provides a practical benefit. It can help prevent counterfeiting. Products like pharmaceuticals, electronics, and luxury items use foil stamping to ensure authenticity. Customers feel more confident buying a product that uses foil because it signals quality and originality.

Applications Across Industries

Hot foil stamping is versatile. Many industries in Malaysia use it to make their products look premium.

Luxury items such as pens, watches, and jewelry often use foil stamping to show elegance. Food and beverage brands use it on premium chocolates, wine bottles, and gourmet products. Cosmetics and skincare brands apply foil to reflect high-end appeal. Even electronics and tech gadgets use it to stand out in crowded retail shelves.

The combination of metallic shine, tactile texture, and visual contrast makes a product look more valuable. It gives your packaging a high-end feel that customers can see and touch.

Designing for Foil Stamping

To get the best results in custom packaging box printing in Malaysia, careful planning is essential.

Smooth and thick papers work best. They allow foil to stick properly and produce a clean finish. Textured or soft-touch papers can make stamping uneven.

Very fine lines or small fonts may not appear clearly when stamped. It is better to focus foil on important elements, such as logos, borders, or patterns. Large foil areas can increase production costs.

Always check your artwork with your printer. Experienced printers can spot problems before production. They can suggest adjustments to make sure the stamping looks perfect.

The Next Level: Digital 3D Hot Stamping and Spot UV

Hot foil stamping has been used for more than 100 years. But technology has improved a lot.

Digital 3D Hot Stamping and Spot UV finishes create multi-dimensional effects. These finishes look striking and feel premium. Unlike traditional foil stamping, digital 3D methods do not require printing plates. This makes setup faster and production more flexible. Small batch runs are also possible, which is ideal for limited edition products.

Combining foil with Spot UV creates a strong visual and tactile impact. The foil pops visually, while Spot UV adds a raised texture that customers can feel. This makes products look and feel premium. It also makes counterfeiting harder because the 3D thickness is difficult to replicate.

Marketing Impact of Hot Foil Stamping

Hot foil stamping is more than decoration—it is a marketing tool. Shiny metallic finishes give an immediate impression of luxury and quality. Customers associate foil-stamped packaging boxes with premium brands.

In Malaysia, these boxes can influence buying decisions. They make products more desirable and memorable. When customers see a product with hot foil stamping, they perceive it as trustworthy and high-end. This perception can lead to more sales, repeat customers, and even word-of-mouth promotion.

Elevate Your Brand with 3D Digital Hot Stamping

Other finishing options, such as cold foil, metallic inks, or varnishes, can differentiate products. However, hot foil stamping remains one of the most effective ways to stand out in packaging box printing in Malaysia. It combines elegance, tactile appeal, and brand protection in one solution.

Digital 3D Hot Stamping with Spot UV is perfect for custom packaging boxes, brochures, or even business cards. It allows your products to look premium and unique without large minimum orders.

Please contact Uniquelink to see samples and get expert guidance. Let us help your products make a strong impression and become impossible to ignore on the shelf.

3 Responses

[…] making 3D foil stamping a responsible choice for modern printing solutions. Furthermore, foil stamping enhances product visibility on shelves, further influencing customer perception and driving sales. […]

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.info/it/register-person?ref=P9L9FQKY

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.