Choosing the Right Paper and Printing Technique for Packaging Boxes in Malaysia

Choosing the right paper and printing technique is one of the most important decisions in packaging box printing Malaysia. A packaging box is not just a box. It protects your product, represents your brand, and creates the first impression when customers see or open it.

Very often, customers judge a product before they even try it. They look at the box, touch it, and feel it. If the packaging looks cheap or weak, customers may think the product inside is the same. This is why choosing the right paper and printing method is so important.

Why Packaging Quality Matters

When packaging fails to protect a product, the problem is bigger than just physical damage. Customers who receive damaged products feel disappointed and angry. Many will leave bad reviews online or decide not to buy from the same brand again.

In today’s market, especially with e-commerce, customer experience is everything. One bad experience can damage your brand reputation. Good packaging helps reduce returns, complaints, and negative feedback.

That is why choosing the correct material and printing technique is not an expense — it is an investment in your brand’s future.

Packaging for Online Sellers and Small Orders

For online sellers and businesses with smaller order quantities, packaging decisions are even more critical. Ordering too many boxes ties up cash and storage space. Ordering too few without planning can cause delays.

This is where digital and short-run printing becomes useful. It allows you to print only what you need, test the market, and adjust your design when necessary. This flexibility helps startups, seasonal products, and new brands manage costs better in packaging box printing Malaysia.

The goal is to balance protection, appearance, cost, and sustainability — all at the same time.

Common Materials Used in Packaging Box Printing Malaysia

In Malaysia, the most commonly used packaging materials are rigid board, box board, and art card. Each material has its own purpose and suits different products and budgets.

All three materials can support premium finishing such as embossing, debossing, spot UV, and hot stamping if used correctly. The final outcome depends on paper thickness, coating, and finishing process. Choosing the right combination ensures your packaging looks good and works well.

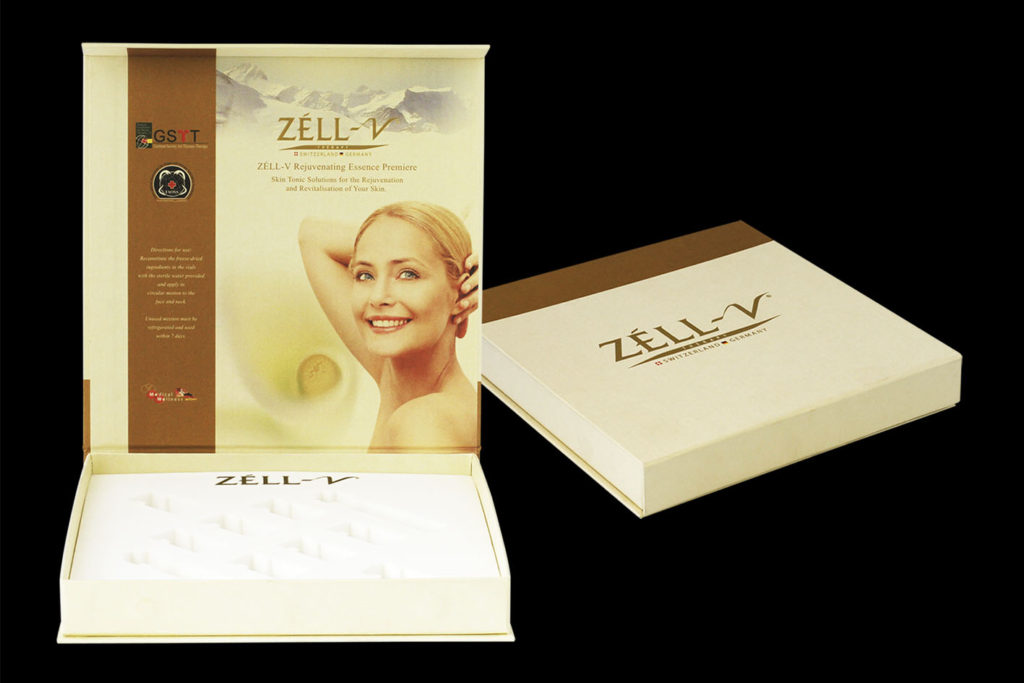

Rigid Board Packaging

Rigid board is thick, solid, and does not fold. It usually ranges from 800 gsm to 1500 gsm. When you hold a rigid box, you can feel the strength and premium quality immediately.

Rigid board packaging is commonly used for jewellery, electronics, premium cosmetics, watches, and luxury gift boxes. It protects the product well and gives customers a good unboxing experience. Many customers even keep the box for storage after use.

However, rigid board costs more to produce and store. It is best used when brand image and product value are more important than cost savings.

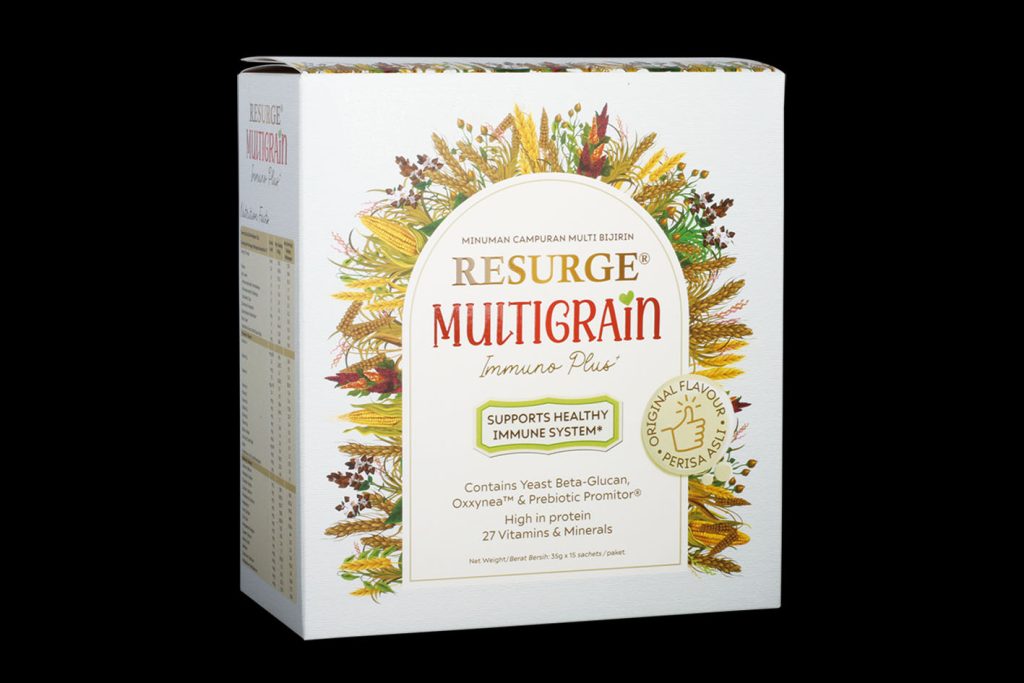

Box Board Packaging

Box board is lighter and more flexible, usually between 250 gsm and 400 gsm. It can be folded and shipped flat, which helps save storage and transportation costs.

This is one of the most widely used materials in packaging box printing Malaysia, especially for food products, toothpaste, pharmaceuticals, and daily consumer goods.

Box board is practical, cost-effective, and suitable for large-volume production. While it does not offer the same protection as rigid board, it works well for non-fragile products and fast-moving goods.

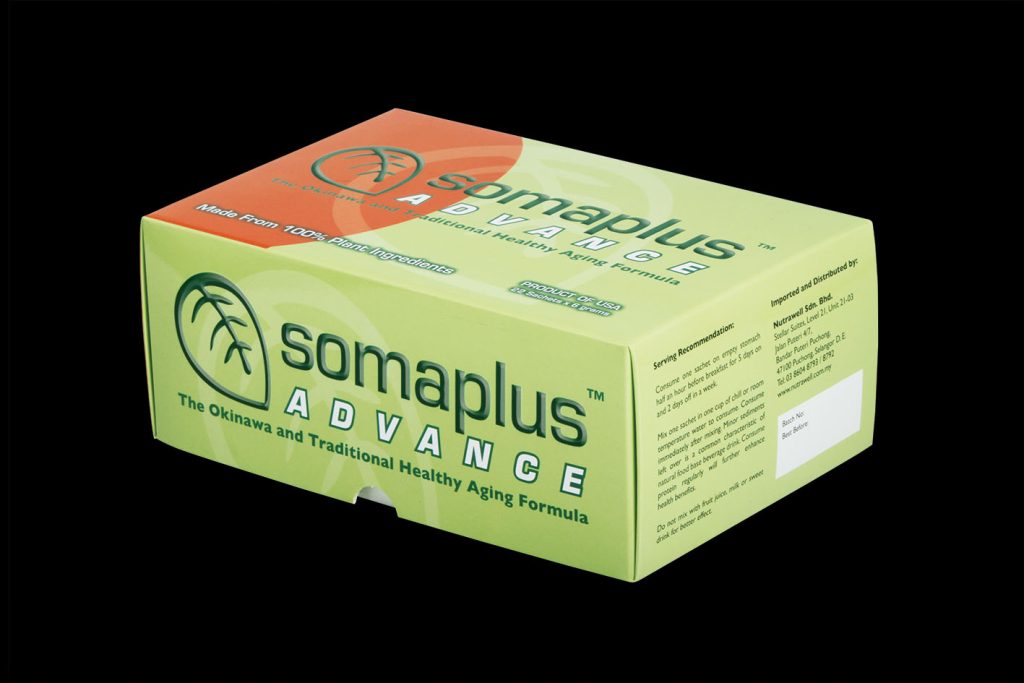

Art Card Packaging

Art card is a coated paper with a smooth surface. It is often used when print quality is very important. Colours appear sharp, clean, and vibrant on art card.

This material is commonly used for cosmetic boxes, gift boxes, and branded retail packaging. It gives a professional and premium look without being too expensive.

Art card is best suited for lighter products that do not require heavy protection. It is popular among brands that want good visual impact at a reasonable cost.

Printing Techniques for Packaging Box Printing in Malaysia

In packaging box printing Malaysia, the two most common printing methods are offset printing and digital printing. Each method serves a different purpose.

Choosing the wrong printing technique can increase cost or delay production. Understanding the difference helps you make better decisions.

Offset Printing for Packaging Boxes

Offset printing is widely used for medium to large-volume orders. It uses metal plates to transfer ink onto paper through rollers.

Although setup takes longer, offset printing becomes very cost-effective when printing large quantities. It produces consistent colours, sharp images, and accurate Pantone colours.

Offset printing also supports many paper types and finishing options. In Malaysia, the typical turnaround time is around three to seven working days, depending on quantity and finishing.

This method is suitable for brands that need large quantities with consistent quality.

Digital Printing for Packaging Boxes

Digital printing does not require printing plates. It prints directly from a digital file. This makes setup fast and flexible.

Digital printing is ideal for short runs, urgent jobs, test marketing, and online businesses. Turnaround time can be as fast as one or two working days.

It also allows variable data printing, such as QR codes, serial numbers, or personalised text. While colour consistency may differ slightly from offset printing, digital printing is very practical for small quantities and fast changes.

How to Choose the Right Printing Technique

If you need a large quantity and consistent branding, offset printing is usually the better choice.

If you need small quantities, fast delivery, or frequent design changes, digital printing is more suitable.

Many online sellers in Malaysia prefer digital printing because it reduces storage needs and allows flexibility. Choosing the right technique helps control cost and improves efficiency.

Sustainable Packaging Printing in Malaysia

Sustainability is becoming more important in packaging box printing Malaysia. Consumers are more aware of environmental issues such as flooding, climate change, and deforestation.

Using FSC®-certified paper and vegetable-based inks helps reduce environmental impact. It also sends a strong message that your brand cares about responsible sourcing and sustainability.

Eco-friendly packaging builds trust and strengthens long-term brand value.

Final Thoughts

Choosing the right paper and printing technique is not just a technical decision. It affects product protection, brand image, cost control, and sustainability.

In a competitive market, businesses that invest in proper packaging box printing Malaysia stand out as reliable and professional brands.

If you are planning your next packaging project and need advice on paper, printing technique, or sustainable solutions, please contact us. We are happy to help you choose the right packaging solution for your business.